High Purity oxygen jenereta opanga okosijeni

Mfundo Yogwirira Ntchito

Mamolekyu a nayitrogeni amakhala ndi kufalikira kwachangu mu ma micropores a zeolite molekyulu sieve, ndipo mamolekyu a okosijeni amakhala ndi kufalikira pang'onopang'ono.Kufalikira kwa madzi ndi mpweya woipa wa carbon dioxide mu mpweya wopanikizidwa ndi kofanana ndi kwa nayitrogeni.Pomaliza, mamolekyu okosijeni amalemeretsedwa kuchokera ku nsanja ya adsorption.Pressure swing adsorption adsorption oxygenation imagwiritsa ntchito mawonekedwe osankhidwa a zeolite molecular sieve, imatenga kuzungulira kwa kutengeka kwamphamvu komanso kutsika kwapang'onopang'ono, ndikupanga mpweya woponderezedwa kulowa munsanja ya adsorption mosinthana kuti izindikire kulekanitsidwa kwa oxygen ndi nayitrogeni, kuti mosalekeza kutulutsa mpweya wambiri. - chiyero ndi mpweya wabwino kwambiri.

Jenereta ya okosijeni ya PSA imatenga zeolite yapamwamba kwambiri ngati adsorbent molingana ndi mfundo ya kuthamanga kwa adsorption.Pansi pa kupanikizika kwina, mpweya umachotsedwa mumlengalenga, woyeretsedwa ndi wowumitsidwa mpweya, ndipo kutengeka kwapanikizidwe ndi decompression desorption kumachitika mu adsorber.Chifukwa cha mphamvu ya aerodynamic, kufalikira kwa nayitrogeni mu ma micropores a zeolite molekyulu sieve ndikokwera kwambiri kuposa mpweya.Nayitrojeni amalowetsedwa ndi zeolite molekyulu sieve, ndipo mpweya umalemeretsedwa mu gawo la mpweya kuti apange mpweya womaliza.Ndiye, pambuyo decompression kwa mpweya kuthamanga, maselo sieve desorbed nayitrogeni ndi zonyansa zina kuzindikira kusinthika.Nthawi zambiri, nsanja ziwiri za adsorption zimayikidwa mu dongosolo, imodzi ya adsorption ndi kupanga mpweya, ndipo ina ya desorption ndi kusinthika.Woyang'anira pulogalamu ya PLC amawongolera kutsegula ndi kutseka kwa valve ya pneumatic kuti nsanja ziwiri zizizungulira mosiyanasiyana, kuti akwaniritse cholinga chopitiriza kupanga mpweya wabwino kwambiri.

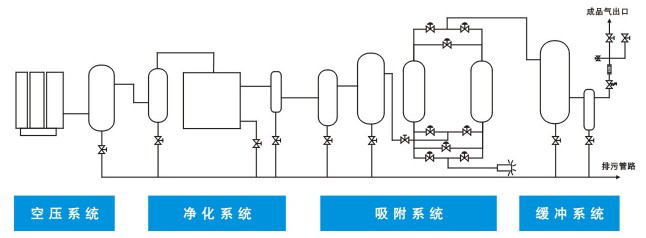

Kuyenda kwadongosolo

Dongosolo lonse lotulutsa mpweya wa okosijeni lili ndi zigawo izi:

Air compressor ➜ tank buffer ➜ compressed air purification device ➜ air process tank ➜ oxygen nitrogen separation device ➜ tank process oxygen.

1. Air kompresa

Monga gwero la mpweya ndi zida zamagetsi za jenereta ya nayitrogeni, kompresa ya mpweya nthawi zambiri imasankhidwa ngati makina opangira ma screw ndi centrifuge kuti ipereke mpweya wokwanira woponderezedwa kwa jenereta ya nayitrogeni kuonetsetsa kuti jenereta ya nayitrogeni ikugwira ntchito bwino.

2. Tanki yosungira

Ntchito za thanki yosungiramo ndi: kubisa, kukhazikika kwa kuthamanga ndi kuziziritsa;Kuti muchepetse kusinthasintha kwa kuthamanga kwa dongosolo, chotsani zonse zonyansa zamadzi amafuta kudzera pa valve yotsitsa pansi, pangani mpweya woponderezedwa kuti udutse bwino pagawo loyeretsera mpweya, ndikuwonetsetsa kuti zidazo zikugwira ntchito modalirika komanso mokhazikika.

3. Wopanikizika mpweya kuyeretsa chipangizo

Mpweya wopanikizidwa kuchokera ku tanki ya bafa umalowetsedwa koyamba mu chipangizo choyeretsera mpweya.Mafuta ambiri, madzi ndi fumbi zimachotsedwa ndi degreaser yapamwamba kwambiri, ndiyeno zimakhazikikanso ndi chowumitsira madzi kuti chichotse madzi, kuchotsa mafuta ndi kuchotsa fumbi ndi fyuluta yabwino, yomwe imatsatiridwa ndi kuyeretsedwa kwakukulu.Malinga ndi momwe amagwirira ntchito, kampani ya Hande idapanga mwapadera makina opukutira mpweya kuti apewe kulowa kwamafuta ndikupereka chitetezo chokwanira cha sieve yama cell.Module yokonzedwa bwino yoyeretsa mpweya imatsimikizira moyo wautumiki wa zeolite molecular sieve.Mpweya woyera womwe umagwiritsidwa ntchito ndi gawoli ukhoza kugwiritsidwa ntchito ngati mpweya wa zida.

4. Tanki yopangira mpweya

Ntchito ya thanki yosungiramo mpweya ndikuchepetsa kugunda kwa mpweya ndi buffer;Kuti kuchepetsa kusinthasintha kwa dongosolo kuthamanga ndi kupanga wothinikizidwa mpweya bwino kudutsa wothinikizidwa mpweya kuyeretsedwa msonkhano, kuti kwathunthu kuchotsa zosafunika mafuta-madzi ndi kuchepetsa katundu wotsatira PSA mpweya ndi nayitrogeni kulekana unit.Pa nthawi yomweyo, pa ntchito kusintha kwa nsanja adsorption, amaperekanso PSA mpweya ndi nayitrogeni kulekana wagawo ndi kuchuluka kwa wothinikizidwa mpweya chofunika kuti mofulumira kuthamanga kukwera mu nthawi yochepa, zomwe zimapangitsa kuthamanga mu adsorption nsanja kuwuka kwa. kupanikizika kogwira ntchito mwamsanga, kuonetsetsa kuti ntchito yodalirika ndi yokhazikika ya zida.

5. Oxygen nitrogen separation unit

Pali nsanja ziwiri za adsorption a ndi B zokhala ndi sieve yapadera yama cell a jenereta ya okosijeni.Pamene mpweya woyera wothinikizidwa umalowa kumapeto kwa nsanja a ndikuyenda mpaka kumapeto kwa sieve ya maselo, nayitrogeni amalowetsedwa ndi iyo, ndipo mpweya wa mankhwala umachokera kumapeto kwa nsanja ya adsorption.Patapita nthawi, sieve ya maselo mu nsanja a imadzaza.Panthawiyi, nsanja imayimitsa yokha kutengera, mpweya woponderezedwa umalowa mu Tower B kuti muyamwitse nayitrogeni ndi kupanga mpweya, ndikubwezeretsanso sefa ya maselo a nsanja a.Kusinthika kwa sieve ya maselo kumachitika potsitsa mwachangu nsanja ya adsorption ku kuthamanga kwa mumlengalenga ndikuchotsa nayitrogeni wa adsorbed.Zinsanja ziwirizi zimapanga ma adsorption ndi kusinthika mosinthana kuti amalize kulekanitsa mpweya ndi nayitrogeni ndikutulutsa mpweya mosalekeza.Njira zomwe zili pamwambazi zimayendetsedwa ndi programmable logic controller (PLC).Mpweya wa okosijeni ukakhazikitsidwa, pulogalamu ya PLC imatsegula valavu yodziyimira yokha kuti itulutse mpweya wosayenerera, kudula mpweya wosakwanira kuti usayendere kumalo ogwiritsira ntchito mpweya, ndikugwiritsa ntchito silencer kuchepetsa phokoso lomwe lili pansi pa 78dba. panthawi yotulutsa mpweya.

6. thanki ya oxygen

Tanki ya okosijeni imagwiritsidwa ntchito kulinganiza kupanikizika ndi kuyera kwa okosijeni wolekanitsidwa ndi njira yolekanitsa ya okosijeni wa nayitrogeni kuti zitsimikizire kupezeka kosalekeza komanso kokhazikika kwa mpweya.Panthawi imodzimodziyo, pambuyo posintha ntchito ya nsanja ya adsorption, imapanganso gawo la mpweya wake mu nsanja ya adsorption, yomwe imathandizira kukwera kwa nsanja ya adsorption, komanso imathandizira kuteteza bedi, ndi kusewera. njira yofunikira kwambiri yothandizira gawo lothandizira pakugwira ntchito kwa zida.

Magawo aukadaulo

Kutulutsa mpweya: 5-300nm3 / h

Kuyera kwa oxygen: 90% - 93%

Kuthamanga kwa oxygen: 0.3MPa

Dongosolo la mame: - 40 ℃ (pampanizo wamba)

Zaukadaulo

1. Mpweya woponderezedwa uli ndi chipangizo choyeretsera mpweya ndi kuyanika.Mpweya waukhondo ndi wowuma umathandizira kukulitsa moyo wautumiki wa sieve ya maselo.

2. Valve yatsopano yoyimitsa pneumatic ili ndi liwiro lotsegula ndi kutseka, palibe kutayikira komanso moyo wautali wautumiki.Itha kukumana ndi kutsegula pafupipafupi komanso kutseka kwa njira yotsatsira ma swing ndipo imakhala yodalirika kwambiri.

3. Njira yabwino yoyendetsera kayendetsedwe kake, kugawa mpweya wofanana, ndi kuchepetsa kuthamanga kwa mpweya.Zigawo zamkati zomwe zimakhala ndi mphamvu zogwiritsira ntchito mphamvu komanso ndalama zogulira

4. Sieve ya molekyulu yokhala ndi mphamvu zambiri, yogwira ntchito kwambiri komanso yochepetsera mphamvu yogwiritsira ntchito mphamvu imasankhidwa kuti iwonetsetse mwanzeru dongosolo lopanda mpweya wokwanira kuti liwonetsetse mpweya wabwino.

5. Zidazi zimakhala ndi machitidwe okhazikika, osavuta, okhazikika, odzipangira okha, osagwira ntchito komanso otsika mtengo pachaka.

6. Iwo utenga PLC ulamuliro, amene angathe kuzindikira zonse basi ntchito.Itha kukhala ndi chipangizo cha okosijeni, kuyenda, kuyeretsa zodziwikiratu komanso dongosolo lakutali.

Munda Wofunsira

1. EAF zitsulo: decarbonization, mpweya kuyaka kutentha, thovu slag kusungunuka, zitsulo kulamulira ndi positi kutentha.

2. Kuchiza kwa madzi onyansa: mpweya wowonjezera mpweya wa sludge, mpweya wa dziwe ndi kutsekereza kwa ozoni.

3. Kusungunuka kwa magalasi: kuyaka kwa okosijeni ndi kusungunuka, kudula, kuchulukitsa magalasi otulutsa ndikutalikitsa moyo wa ng'anjo.

4. Kupaka utoto ndi kupanga mapepala: Blechini ya chlorine imasinthidwa kukhala bleaching wowonjezera okosijeni kuti apereke mankhwala otsika mtengo a okosijeni ndi zimbudzi.

5. Kusungunula zitsulo zopanda ferrous: Kuchulukitsa kwa okosijeni kumafunika pakusungunula chitsulo, zinki, faifi tambala ndi lead, ndipo njira ya PSA ikusintha pang'onopang'ono njira ya cryogenic.

6. Oxygen kwa makampani petrochemical ndi makampani mankhwala: mpweya wolemera ntchito m'malo mpweya kwa makutidwe ndi okosijeni anachita mu zimene mpweya mu makampani petrochemical ndi makampani mankhwala, amene akhoza kusintha anachita liwiro ndi linanena bungwe mankhwala mankhwala.

7. Ore processing: amagwiritsidwa ntchito mu golide ndi njira zina zopangira kuti apititse patsogolo kuchuluka kwa zitsulo zamtengo wapatali.

8. Zamoyo zam'madzi: mpweya wowonjezera mpweya ukhoza kuwonjezera mpweya wosungunuka m'madzi, kuonjezera kwambiri kupanga nsomba, kunyamula mpweya wa nsomba zamoyo komanso kuweta nsomba mozama.

9. Kuwotchera: Kuchulukitsa kwa okosijeni kumalowa m'malo mwa mpweya kuti upereke okosijeni wa aerobic fermentation, zomwe zingathandize kwambiri kuti madzi akumwa azikhala bwino.

10. Ozoni: perekani mpweya ku jenereta ya ozoni kuti muchepetse mpweya wa okosijeni.

11. Chipatala: perekani mpweya wopuma bedi.Kuyera, kutuluka ndi kupanikizika kumakhala kokhazikika komanso kosinthika kuti akwaniritse zosowa za makasitomala osiyanasiyana.